LINE STOPPING

Safely Isolate Live Pipelines Without Shutting Down Your System.

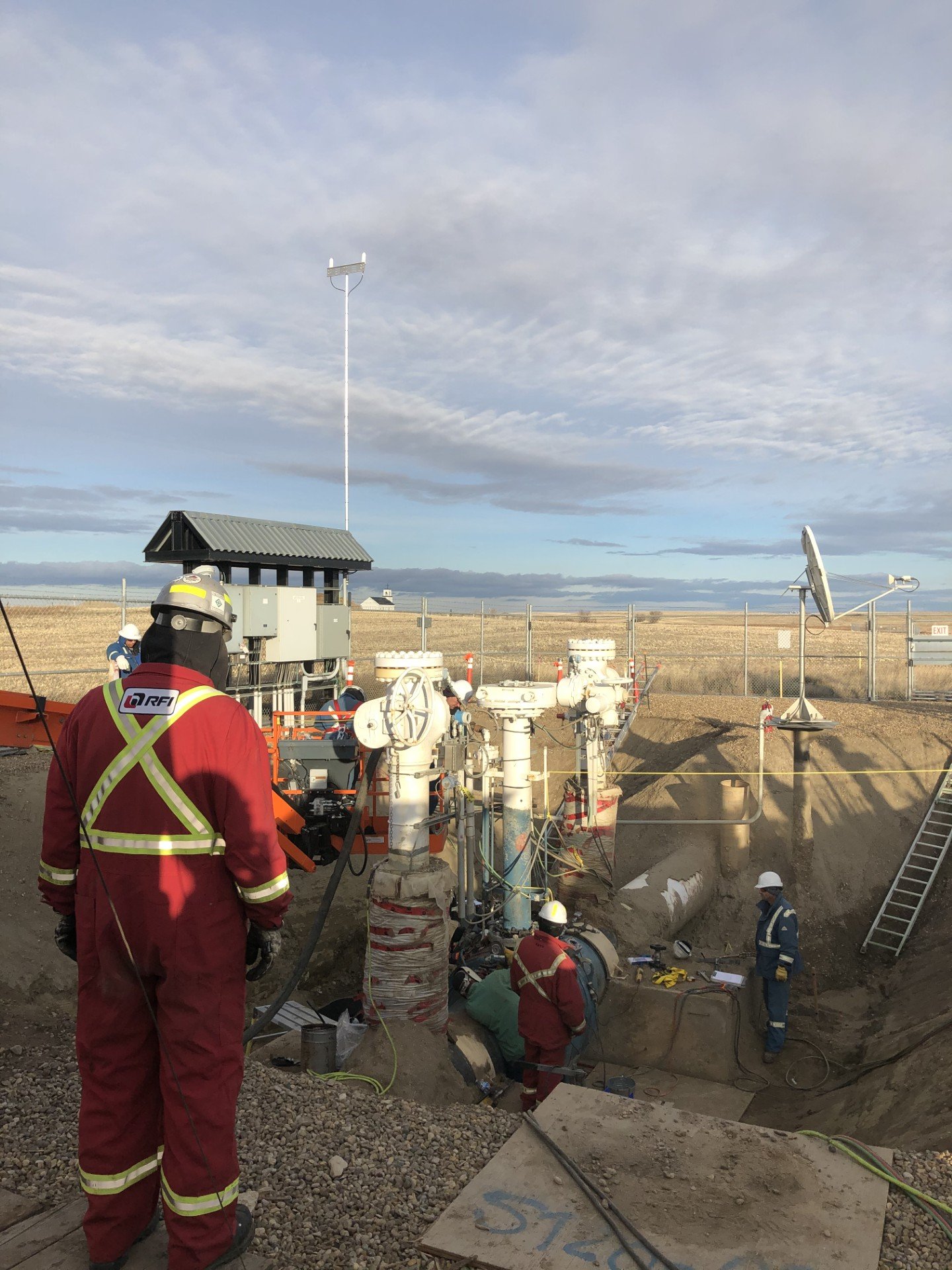

Line stopping allows you to temporarily block flow in pressurized piping systems so you can perform maintenance, tie-ins, or emergency repairs without costly shutdowns. Using engineered fittings and proven stopple technology, RFI provides safe, reliable isolation with minimal disruption to your operations.

WHY LINE STOPPING

• Maintain Production: Isolated on the section you need while the rest of the system stays online

• Emergency Ready: Rapid deployment for leak control, valve replacement, or unplanned outages

• Flexible Configurations: Single or double-block-and-bleed (DBB) systems with custom bypass options

• Safe & Engineered: Full engineering review, procedure control, and QA documentation

Note: All work is performed in accordance with engineered procedures and jurisdictional code compliance.

Capabilities

High-Pressure Systems

Sizes: 2”-24”

Pressures: Up to ~750 PSI

Temperatures: Up to 242ºC (462ºF)

Low-Pressure Systems:

Sizes: 3”-72”

Pressures: Up to ~100 PSI

Temperatures: 0ºC - 242ºC (32ºF - 462ºF)

Typical Use Cases

Valve Replacements & Upgrades

Facility Tie-Ins & Expansions

Emergency Leak Control

Pipeline Repairs & Cutovers

Isolation Of Selections For Inspection/Testing

System Types

High-Pressure Pivot-Head Isolation Systems (Single or DBB)

High-Pressure Single-Port DBB Systems

Low-Pressure Kevlar® Isolation Bag Systems

Low-Pressure Short-Stop Sealing Cup Applications

Bypass Options

We design custom bypasses to keep your process flowing while the line stop is in place.

Final pressure/temperature/material compatibility is confirmed by engineering review for each job.

HOW IT WORKS

Engineering & Planning

Review of system details, load calculations, and permits

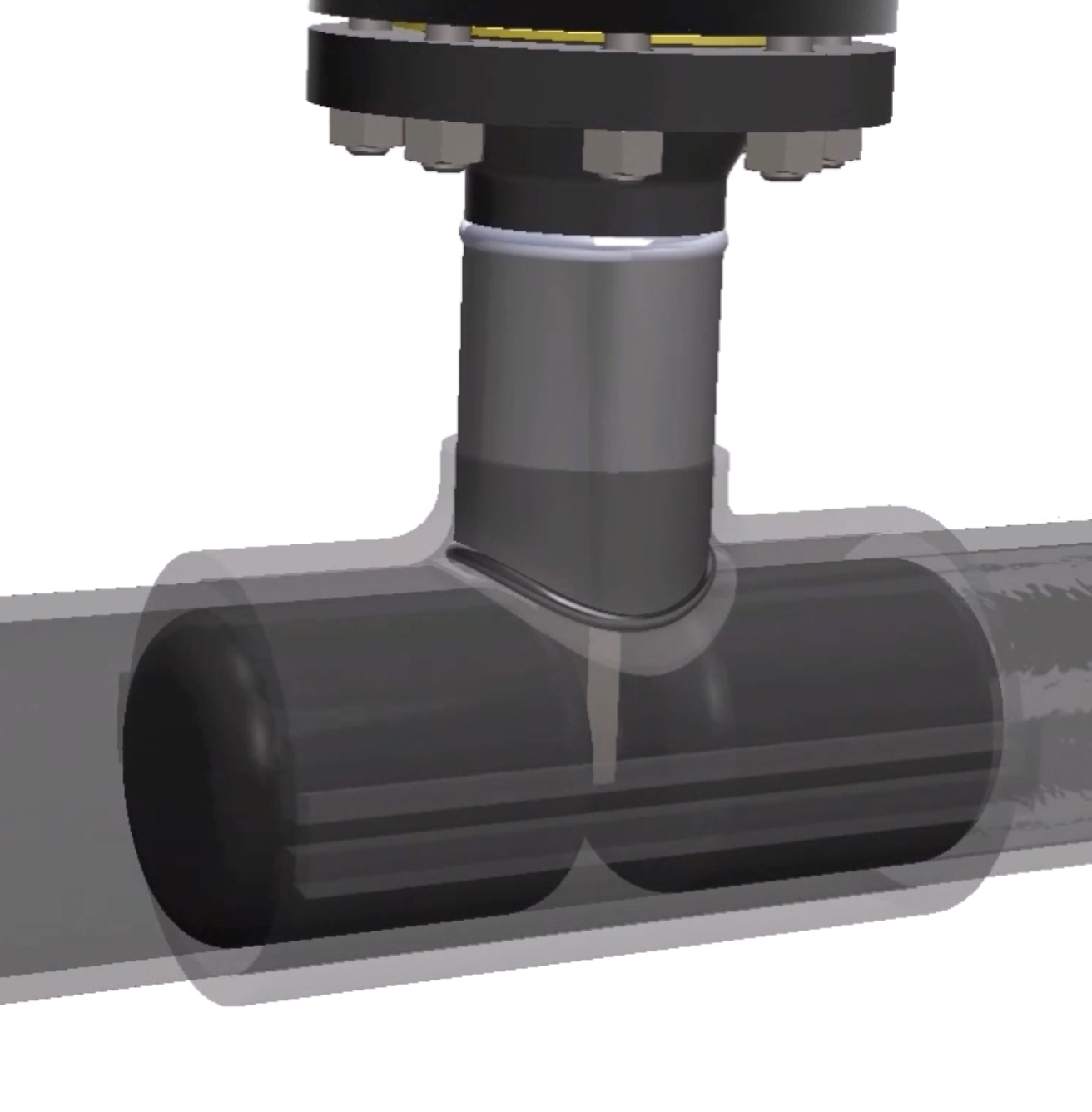

Hot Tap Connection

Installation of a branch fitting and isolation valve

Stopple Insertion

Deployment of sealing head or bag into the pressurized line

Flow Isolation

Line stop activated; optional bypass maintains product flow

Work Performed

Maintenance, replacement, or tie-ins completed safely

Removal & Restoration

Stopple retracted, valve closed, completion flange installed

LINE STOP

QUALITY CONTROLS

• IN-HOUSE NDT & WELD QA

• HAZOPS/ PERMITS ADMINISTRATION

• QC DOSSIERS WITH WELD MAPS, WPS/PQR/WPQS, AND PRESSURE TEST RECORDS

• COMPLIANCE WITH CSA/ASME CODES AND PROVINCIAL/STATE REGULATIONS

SAFETY & COMPLIANCE

• ENGINEERED PROCEDURES & HAZARD ASSESSMENTS

• QUALIFIED IN-SERVICE WELDERS

• NDT BEFORE/AFTER AS REQUIRED

• PRESSURE BOUNDARY INTEGRITY VERIFICATION

• FULL TURNOVER DOCUMENTATION

FREQUENTLY ASKED QUESTIONS

-

Single block provides isolation; DBB adds an extra sealing barrier and vent/bleed for added safety.

-

Yes–line stops require a hot tap connection and isolation valve efore inserting the stopple.

-

Yes–we design bypasses to keep product moving while the line is isolated.

-

All work is performed to applicable CSA/ASME standards and jurisdictional requirements.