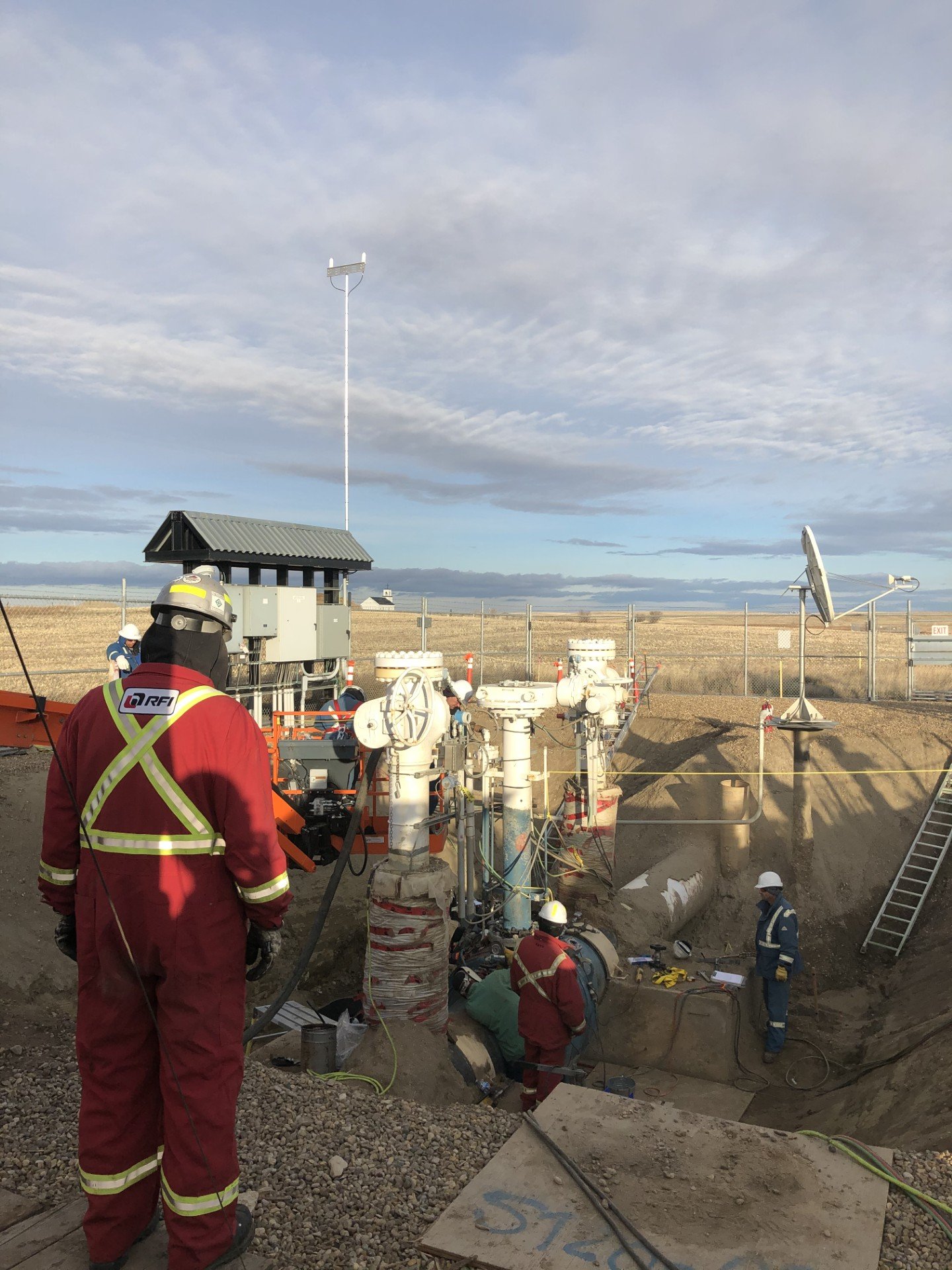

Hot Tapping

Reliable In-Service Connections Without Shutdowns

Add branches, instrumentation, or tie-ins to live pipelines, tanks, and vessels while maintaining flow and pressure. Our certified in-service welders, engineered fittings, and purpose-built tapping equipment let you complete modifications quickly and safely–reducing downtime, emissions, and cost.

WHY HOT TAP

• No Shutdown Required: Maintain production and avoid costly outages

• Safe, Engineered Process: Full engineering review, procedure control, and QA documentation

• Versatile Applications: Tie-ins, bypasses, instrumentation ports, wellhead work, and more

• Compatible With Most Media: Oil, gas, water, steam, chemicals–subject to engineering

Note: All work is performed under engineered procedures and jurisdictional code compliance.

Capabilities

Diameter:

¼” to 48” outlet size

Pressure Envelope:

Up to 5,000 PSI (35,000 kPA)

Design Temperatures:

Up to 371ºC (700ºF)

Extend Reach/Below-Grade Risers:

Up to ~6.1m (20ft) for 2”-8” branches; 10”+ branches up to ~3.5m (10ft)

Branch & Tap Types

Reducing branches (size reduction)

Olets: Weldolet®, Sockolet®, Threadolet®

Split Tee (size-on-size)

Extended-Reach/Below-Grade Risers

Valve Drill-Out

Thermowell, Pig Signal, & Injection Nozzles

Final pressure/temperature/material compatibility is confirmed case-by-case following engineering review and site conditions.

Typical Use Cases

Facility Expansion & Tie-Ins

Adding bypasses for future connections

Installing instrumentation (thermowells, pig signals, injection ports)

Tank nozzle additions for mixing, sampling, or transfers

Wellhead re-entry preparation (with cold tap, where appropriate)

Engineering & Work Package

Application review, calculations, materials selection, and permits

Fit-Up & In-Service Welding

Application review, calculations, materials selection, and permits

HOW IT WORKS

Pressure-Rated Valve Installation

Isolation valve torqued, tested, and locked open for tapping

Tapping

Boring bar advances through the valve, removes a coupon, and retracts with positive containment

Completion

Valve closed; flange/branch prepared for your tie-in or instrument. Documentation delivered

EXTENDED REACH

HOT TAP

QUALITY CONTROLS

• IN-HOUSE NDT (RT/UT/MT/PT AS APPLICABLE)

• HAZOPS/PERMITS ADMINISTRATION

• QC DOSSIERS WITH WELD MAPS, WPS/PQR/WPQS, AND PRESSURE TEST RECORDS

• COMPLIANCE WITH APPLICABLE CSA/ASME CODES AND PROVINCIAL/STATE REGULATIONS

NEED IN-SERVICE MODIFICATION WITHOUT SHUTDOWN?

OUR SPECIALISTS ARE READY TO HELP.

COLD TAP (MECHANICAL TAPPING)

Some scopes call for a mechanical col tap–a drill-and-connect method using a mechanical tee where in-service welding is not desired.

Cold Tap Applications

Pressure confirmation and de-pressurizing

New construction or outage branch installations without purging stagnant fluids/gas

Wellhead re-entry and abandonment cut-and-cap

Full pipeline cut-and-cap programs

Mechanical/self-sealing branch fittings, including temporary or HDPE/PVC connections

QUALITY CONTROLS

• ENGINEERED PROCEDURES AND HAZARD ASSESSMENTS (HAZOPS)

• QUALIFIED IN-SERVICE WELDERS (WPS/PQR/WPQS)

• NDT EFORE/AFTER AS NEEDED

• PRESSURE OUNDARY INTEGRITY VERIFICATION

• FULL DOCUMENTATION TURNOVER

FREQUENTLY ASKED QUESTIONS

-

Up to ~5,000 PSI & ~371ºC (700ºF), subject to. engineering review, materials, and fitting selection.

-

In many cases, we recommend mechanical cold tap or specialty fittings–the final approach is determined yy engineering and the host material.

-

Not for the tap itslef. If you require a tie-in cutover, we can help minimize downtime.

-

Work is performed to applicale CSA/ASME and jurisdictional requirements.